©

Smart-Growth

The future of crystals is growing

New Vision

SMART-Growth revolutionizes crystal production with innovative solutions. Using sensors, AI tools, and digital models, we enhance both output and quality. Smart Growth offers AI enabled control of crystal growth via CZ process based on ZDM principles to improve crystal yield, reduce critical rare material and energy wastage in the manufacturing process benefitting both crystal manufacturers and downstream users.

The Project

THE PROBLEM

THE SOLUTION

THE RESULTS

The current state of crystal growth presents several critical challenges. The industry is characterized by highly hostile process conditions, where there is a significant risk of contamination, and production times are notably long. Moreover, it heavily depends on the use of costly rare earth materials and consumes a substantial amount of energy, making the process both expensive and resource-intensive. Additionally, there are numerous process parameters that are difficult to measure and control, further complicating efforts to optimize efficiency and ensure consistent product quality.

The AI-enhanced ZDM approach in crystal growing is expected to deliver several key outcomes. These include an improved yield in crystal production, leading to higher efficiency. Additionally, energy consumption and material waste will be significantly reduced, lowering both costs and environmental impact. Finally, the quality of the grown crystals will be improved, ensuring more consistent and reliable output.

SMART-Growth projects aim to leverage AI-enhanced Zero Defect Manufacturing (ZDM) approaches to improve crystal growing. This includes developing advanced radiation and non-radiation sensors to monitor molten material and furnace conditions. AI tools, using digital process models and historical data, help optimize the relationship between process parameters, crystal quality, and yield. Additionally, the integration of Digital Twin technology and Cyber Physical Systems enables predictive control, using AI-driven insights to optimize the process in real time.

Applications

The technologies developed by the SMART-Growth project can be applied to a wide range of sectors, with increasingly innovative synergies emerging in both industrial and regional development fields.

REGIONAL SYNERGIES

MANUFACTURING SYNERGIES

A project for local development

Sardinia

West Romania

Thuringia

Sardinia is beautiful for its stunning beaches with crystal-clear waters, rugged landscapes, rich history, and unique culture. The island offers a mix of ancient archaeological sites, like nuraghe, charming villages, delicious local cuisine, and a slower, relaxed pace of life. Located on the island, our partner Filar leads the way in innovative crystal processing and growth, driving advancement in this industry and bringing new opportunities to the region.

Western Romania stands out for its beautiful landscapes, rich history, and diverse cultural influences. The region is home to rolling hills, medieval towns, and a blend of Romanian, Hungarian, and German traditions, creating a unique atmosphere. It's also a growing center for innovation and industry, with a strong connection to the rest of Europe. Based in the region, our partner WUT leads the way in digital twin technology and cyber-physical systems, driving technological progress and contributing to the region’s development.

Thuringia is known for its lush forests, charming towns, and a deep-rooted cultural heritage. The region boasts historic architecture, picturesque landscapes, and a thriving tradition in science and innovation. It is also home to a strong industrial sector, particularly in optics and precision engineering. Based in Thuringia, our partner Fraunhofer IOF leads in applied research and development in the field of optics and precision engineering, driving advancements in this industry and contributing to the region’s reputation as a center of scientific excellence.

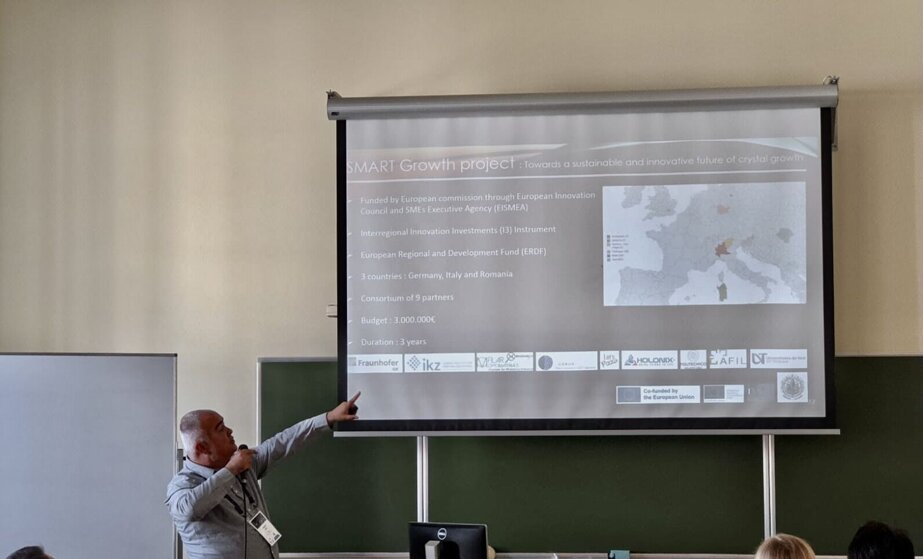

I3 Instruments

The Interregional innovation investments instrument as part of the European Regional and Development Fund (ERDF) aims at supporting interregional innovation projects in their commercialization and scale-up phases giving them the tools to overcome regulatory and other barriers and bring their project to investment level.

SMART-Growth aims to support and develop the regions of Sardinia, Bolzano, Thuringia and the region of Western Romania.

News

The Project is partner of the AI4manufacturing Network

Co-funded by the European Union.

Views and opinions expressed are however those of the authors) only and do not necessarily reflect those of the European Union or I3 instrument. Neither the European Union nor the granting authority can be held responsible for them.

©

SMART-Growth Shines at CMCEE 2024

SMART-Growth Shines at CMCEE 2024 8th European Crystal Growth Conference in Warsaw

8th European Crystal Growth Conference in Warsaw Live meeting at FILAR

Live meeting at FILAR ICAM - Advanced Environmental Research Institute

ICAM - Advanced Environmental Research Institute